Processing Case | All processes were completed in one clamping, and the efficiency of the through-spindle machine soared

The through-spindle machine, also known as the through-spindle CNC lathe, is a precision processing equipment that can simultaneously complete various combined compound processing such as turning, drilling, boring, tapping, and engraving in one go. It is mainly applied in the batch processing of precision hardware, shafts and other irregular non-standard parts, and is suitable for high-precision processing industries such as aerospace, automotive manufacturing, and medical devices.

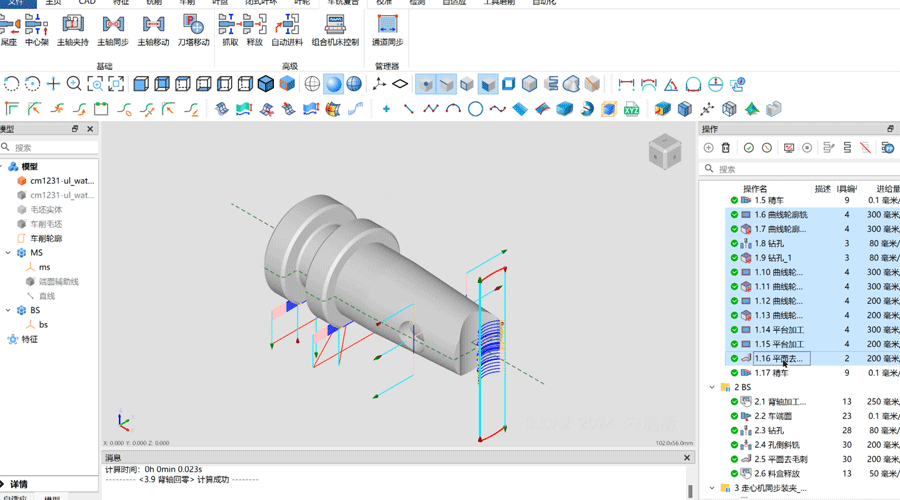

The Qianji CAM, in collaboration with the Huazhong CNC 808D through-feed machine milling compound system, carried out multi-channel collaborative processing on the Jiecheng CNC D206 six-axis through-feed machine, successfully completing the processing of the outlet pipe and valve sleeve products.

To meet the demand for simultaneous processing with two spindles, this product processing was programmed in sequence for the feeding and turning and milling of the stop block tool at the spindle end, the turning and milling of the back spindle end, and the release of the material box. Then, the programming for part processing was carried out, completing the work of spindle movement, clamping state, synchronous state of the two spindles, and predefined position of the cutting tool. The synchronization of dual-channel operations, part processing and multi-channel post-output are carried out through the channel synchronization manager in the QJCAM turning and milling compound module, achieving a doubling of efficiency.

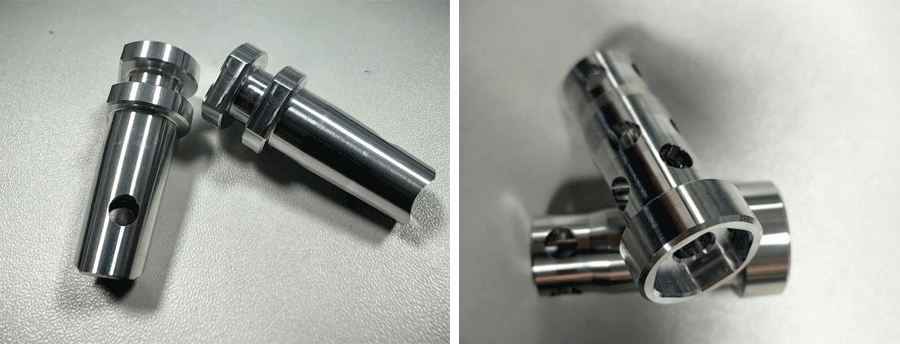

Finished product display: