Laser processing of QJCAM.PCD super-hard alloy cutting tools

Hard alloy materials, featuring high strength, high hardness, high oxidation resistance and high corrosion resistance, have significant advantages in the field of cutting tools. However, the traditional PCD tool manufacturing technology has problems such as low processing efficiency and large limitations.

Laser processing technology, with its revolutionary non-contact processing method, has brought new possibilities to the manufacturing of cemented carbide tools. It not only overcomes the limitations of traditional processing methods, improving processing efficiency and accuracy, but also significantly enhances the cutting performance and service life of cemented carbide tools through diverse application means.

QJCAM.PCD is a CAM software specifically designed for laser processing of super-hard alloy tools. It is applied to the laser processing of standard and non-standard tools (such as forming tools, combined tools, etc.). By automatically detecting the welding or clamping errors of PCD inserts, it builds the rear tool face and generates the laser processing tool path, achieving smooth one-click processing.

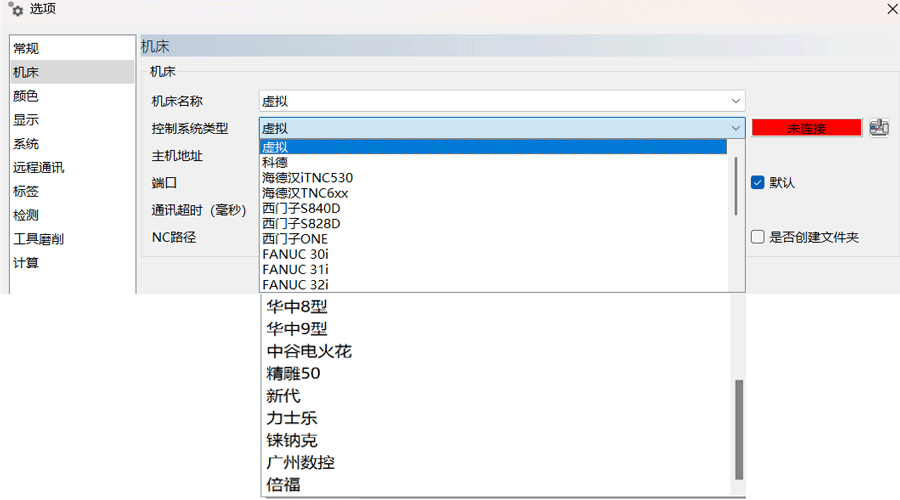

Support multiple numerical control systems

Supports a variety of CNC systems such as Heidenhain, Siemens, Fanuc, Rexroth, Huazhong CNC, Dalian Kede, Xindai, and Renak.

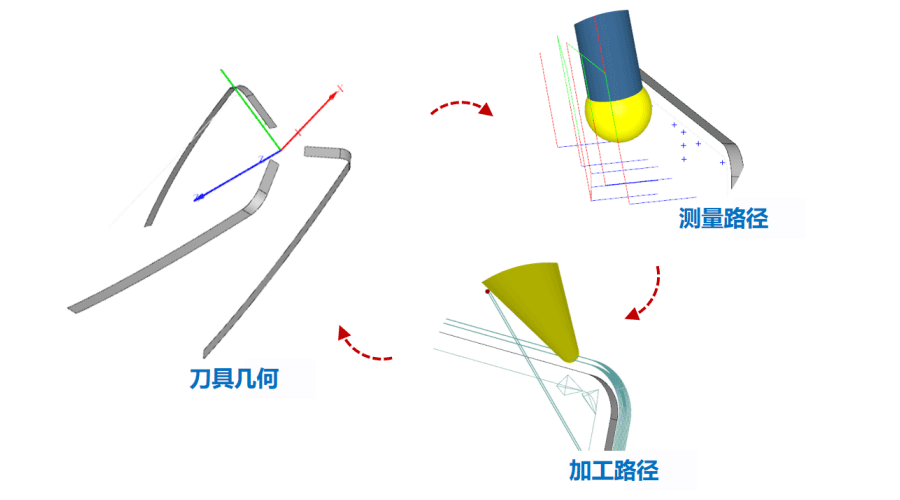

Convenient parametric programming

Users only need to input DXF graphics and do not need three-dimensional digital models to perform programming operations within the software. Tool geometry data, in-machine measurement paths, and laser processing tool paths can all be defined through parameters.

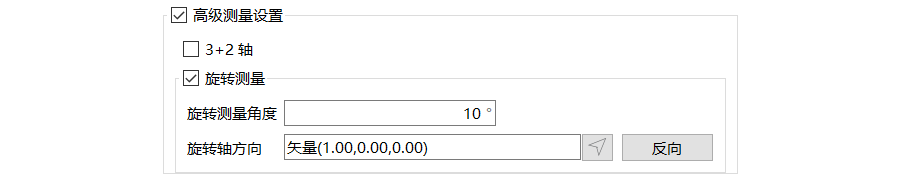

Precise rotation measurement

Virtual measurement points are planned based on the planar contour line, and rotational measurement can accurately locate the position to be measured according to the radius depth.

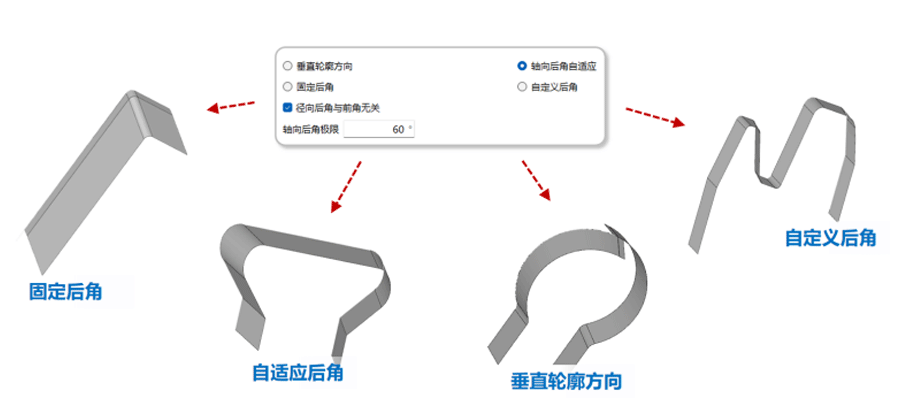

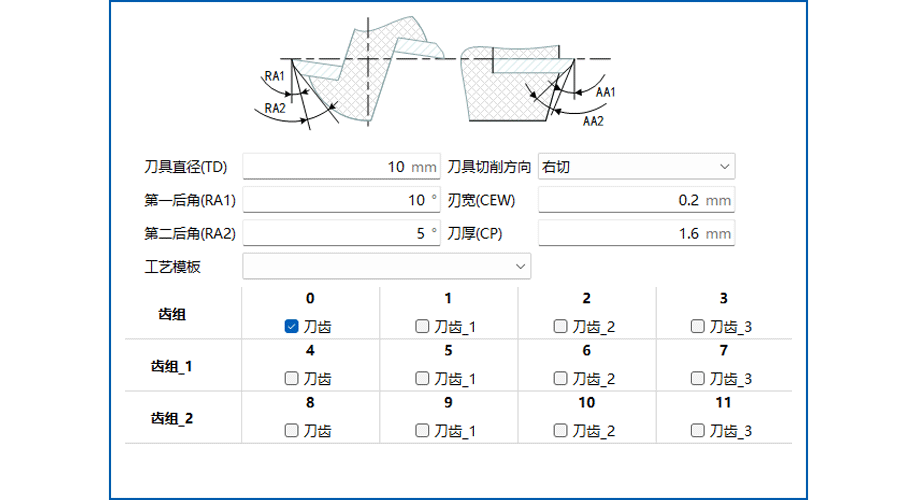

Support multiple rear cutter face structures

Supports single and double relief Angle modes, and the shaft diameter and relief Angle can be defined. It provides multiple rear tool face construction methods, which can meet the processing requirements of various types of tools.

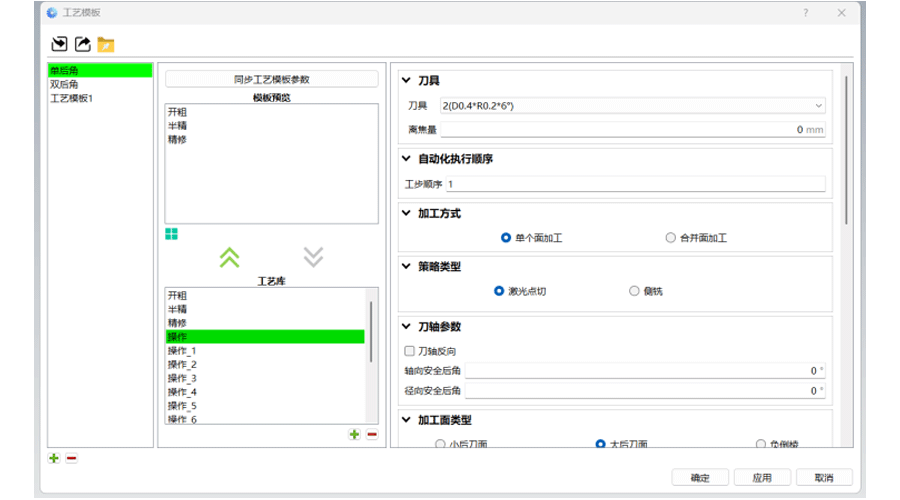

An efficient process parameter library

Users can establish a library of laser processing process parameters, solidify their experience, and create tool paths that can be directly called to fill programming parameters, significantly reducing repetitive operations during the programming process.

Flexible mode switching

Users can switch between three working modes: processing, camera, and simulation. Different modes correspond to different working scenarios.

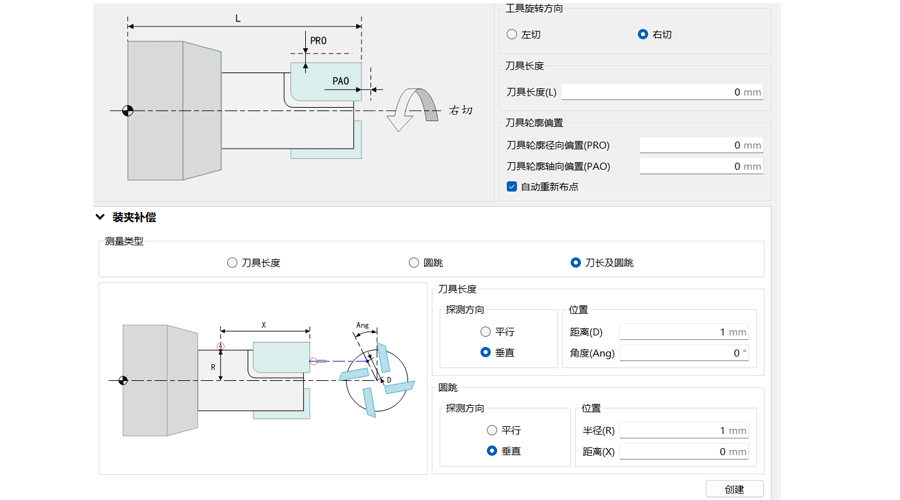

Tool length and circular jump compensation function

Through parametric point layout, the possible length errors in tool clamping are corrected and the influence of tool shank runout on the machining accuracy is reduced.

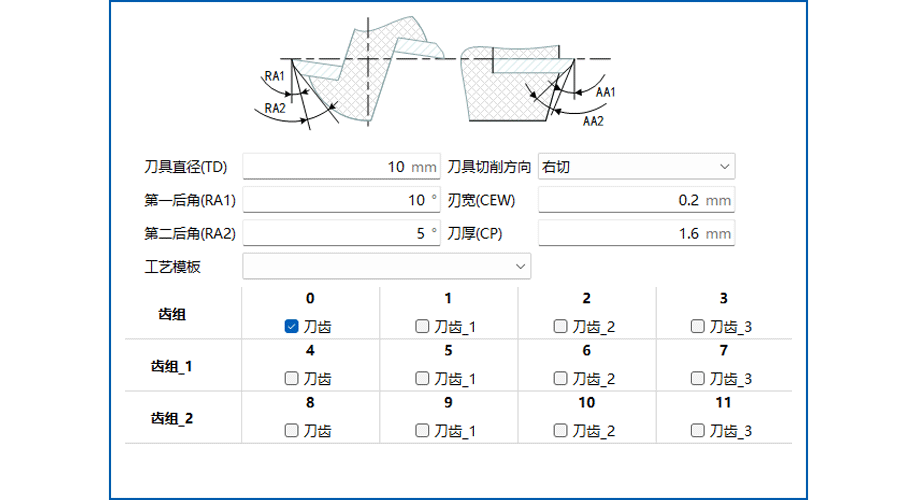

Customizable peripheral edge and spiral knife templates are available

Templates can be customized for users' standard tools. There is no need to import DXF graphics. The entire project can be set up through the parameter configuration shown in the diagram, and it can be started with one click.

(Standard knife template)

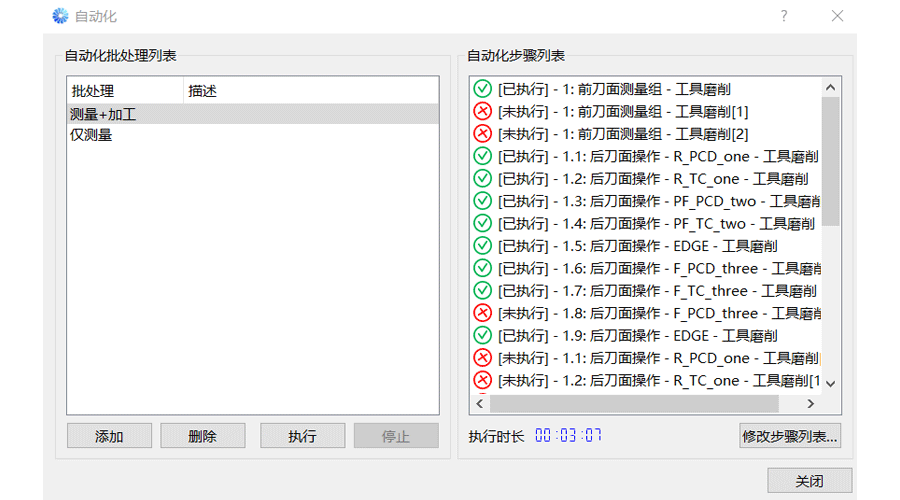

Support automated processing

The automatic sending of programs and the return of measurement results, as well as the monitoring of machine tool status, can achieve the series connection of measurement and processing programs. All programs are executed through software-driven equipment without the need for manual transmission.

QJCAM.PCD has outstanding advantages both in the coverage of tool types and in the adaptability of production and manufacturing. It has been widely applied in domestic medium and high-end laser linkage processing equipment. With professional capabilities and wide applicability, it has become an indispensable CAM software in the domestic precision tool manufacturing field.

If you want to learn more about PCD tool laser processing, please scan the QR code below to reserve a live stream. On February 20th (next Thursday) at 19:00, Qianji Intelligent Live Room will bring you professional explanations and case sharing.